无承载面嵌件螺母NB系列(No Bearing Surface Inserts),从材质上分为NBB(Brass铜嵌件),NBC(Carbon steel碳钢嵌件),NBS(Stainless steel不锈钢嵌件)

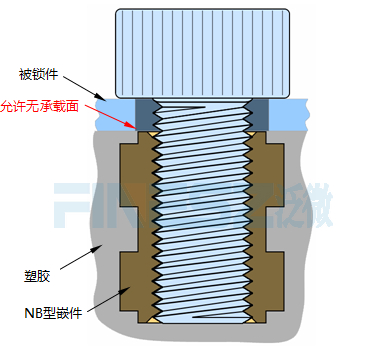

无承载面螺母是相对于常规嵌件螺母而言的。常规嵌件螺母(如GB809)在螺钉锁紧过程中,被连接零件的孔需接触螺母端面使得螺母本身(而不是塑料)承载负荷,SHK、BTH等带法兰面嵌件螺母加大了头径更是为了分布承载负荷,而NB型螺母特意减小了螺母的端面直径,在锁紧过程中无需承载面,故称之为无承载面螺母或非承载面螺母。

NB型螺母外径较常规格螺母大,长度选型也较常规螺母长,是一种高强度拉拔力的嵌件,其扭出力(在螺栓拧到底的情况下)甚至大幅超过12.9级螺栓本身的安全拧紧力。同时NB型螺母注塑成型后(因端面直径小)塑胶平面简约美观。

1,自动化安装。NB型嵌件两端台阶利于机械手臂抓取,配合振动盘自动化将嵌件插入模具顶针,省去人工喂料,从而提高作业效率。

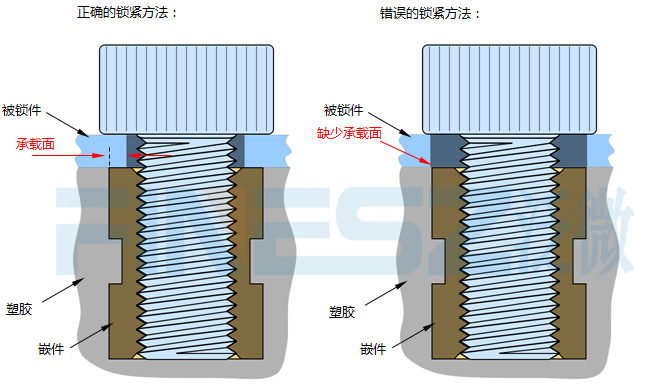

2,允许无承载面。在常规嵌件的锁紧方式中,被锁紧件孔径应略大于螺钉直径且小于螺母端面直径,使得螺母本身承载螺钉拧紧产生的载荷,这是默认的安全锁紧方式。而如果被锁件孔径大于螺母端面直径,则螺钉锁紧产生的载荷由嵌件与塑胶孔的结合力承担,这增加了嵌件脱出的风险,如下图所示

采用NB型螺母,其高强度的拉拔力性能,允许被锁件孔径不作严格要求,如下图所示:

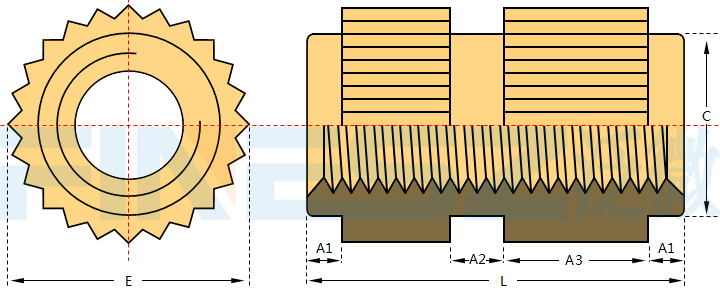

| 螺纹*牙距 | 型号 | 螺纹 代号 |

L ±0.1 |

E ±0.1 |

C ±0.1 |

A1 | A2 | A3 | 螺纹孔径 +0.1 |

||

| 黄铜 | 碳钢 | 不锈钢 | |||||||||

| M3*0.5 | NBB | NBC | NBS | M3 | 8 | 6 | 4.3 | 1.20 | 1.50 | 2.60 | 2.5 |

| NBB | NBC | NBS | M3 | 10 | 1.5 | 2.00 | 3.50 | ||||

| NBB | NBC | NBS | M3 | 12 | 1.5 | 2.00 | 5.00 | ||||

| NBB | NBC | NBS | M3 | 15 | 1.5 | 2.50 | 6.50 | ||||

| M4*0.7 | NBB | NBC | NBS | M4 | 10 | 7.5 | 5.5 | 1.5 | 2.00 | 3.50 | 3.3 |

| NBB | NBC | NBS | M4 | 12 | 1.5 | 2.00 | 5.00 | ||||

| NBB | NBC | NBS | M4 | 15 | 1.5 | 2.50 | 6.50 | ||||

| NBB | NBC | NBS | M4 | 20 | 1.5 | 3.00 | 9.00 | ||||

| M5*0.8 | NBB | NBC | NBS | M5 | 10 | 9 | 6.8 | 1.5 | 2.00 | 3.50 | 4.2 |

| NBB | NBC | NBS | M5 | 12 | 1.5 | 2.00 | 5.00 | ||||

| NBB | NBC | NBS | M5 | 15 | 1.5 | 2.50 | 6.50 | ||||

| NBB | NBC | NBS | M5 | 20 | 1.5 | 3.00 | 9.00 | ||||

| NBB | NBC | NBS | M5 | 25 | 1.5 | 3.00 | 12.00 | ||||

| M6*1.0 | NBB | NBC | NBS | M6 | 12 | 11 | 8.25 | 1.5 | 2.00 | 5.00 | 5.0 |

| NBB | NBC | NBS | M6 | 15 | 1.5 | 2.50 | 6.50 | ||||

| NBB | NBC | NBS | M6 | 20 | 1.5 | 3.00 | 9.00 | ||||

| NBB | NBC | NBS | M6 | 25 | 1.5 | 3.00 | 12.00 | ||||

| 螺纹*牙距 | 型号 | 螺纹 代号 |

L ±.004 |

E ±.004 |

C ±.004 |

A1 | A2 | A3 | 螺纹孔径 +.003 |

||

| 黄铜 | 碳钢 | 不锈钢 | |||||||||

| #4-40 | NBB | NBC | NBS | 440 | .313 | .236 | .169 | .05 | .06 | .094 | .090 |

| NBB | NBC | NBS | 440 | .374 | .06 | .078 | .117 | ||||

| NBB | NBC | NBS | 440 | .500 | .06 | .078 | .212 | ||||

| NBB | NBC | NBS | 440 | .625 | .06 | .100 | .250 | ||||

| #6-32 | NBB | NBC | NBS | 632 | .374 | .250 | .185 | .06 | .078 | .117 | .110 |

| NBB | NBC | NBS | 632 | .500 | .06 | .078 | .212 | ||||

| NBB | NBC | NBS | 632 | .625 | .06 | .100 | .250 | ||||

| NBB | NBC | NBS | 632 | .750 | .06 | .118 | .325 | ||||

| #8-32 | NBB | NBC | NBS | 832 | .374 | .315 | .236 | .06 | .078 | .117 | .134 |

| NBB | NBC | NBS | 832 | .500 | .06 | .078 | .212 | ||||

| NBB | NBC | NBS | 832 | .625 | .06 | .100 | .250 | ||||

| NBB | NBC | NBS | 832 | .750 | .06 | .118 | .325 | ||||

| #10-32 | NBB | NBC | NBS | 032 | .374 | .354 | .267 | .06 | .078 | .117 | .161 |

| NBB | NBC | NBS | 032 | .500 | .06 | .078 | .212 | ||||

| NBB | NBC | NBS | 032 | .625 | .06 | .100 | .250 | ||||

| NBB | NBC | NBS | 032 | .750 | .06 | .118 | .325 | ||||

| NBB | NBC | NBS | 032 | 1.00 | .06 | .118 | .500 | ||||

| 1/4-20 | NBB | NBC | NBS | 0420 | .500 | .433 | .325 | .06 | .078 | .212 | .200 |

| NBB | NBC | NBS | 0420 | .625 | .06 | .100 | .250 | ||||

| NBB | NBC | NBS | 0420 | .750 | .06 | .118 | .325 | ||||

| NBB | NBC | NBS | 0420 | 1.00 | .06 | .118 | .500 | ||||

| 规格 | 基材ABS | 基材PC | ||

| 扭出力N.m | 拉出力 N | 扭出力N.m | 拉出力 N | |

| NB-M3-8 | 4.4 | 2080 | 6.2 | 2770 |

| NB-M4-10 | 6.1 | 2560 | 8.5 | 3400 |

| NB-M5-10 | 9 | 2800 | 12.5 | 3740 |

| NB-M6-12 | 18 | 4360 | 25 | 5800 |

| 类型 | 材质 | 元素名称及化学成份(%) | |||||

| 铜(Cu) | 锌(Zn) | 铅(Pb) | 锡(Sn) | 铁(Fe) | 杂质总和 | ||

| NBB | C3604黄铜 | 57-61 | 余量 | 1.8-3.7 | Fe+Sn≤1.2 | ≤0.5 | ≤0.3 |

| 类型 | 使用的材质 | 元素名称及化学成份(%) | |||||||

| 碳(C) | 锰(Mn) | 硅(Si) | 磷(P) | 硫(S) | 镍(Ni) | 钼(Mo) | 铬(Cr) | ||

| NBS | SUS303不锈钢 | ≤0.15 | ≤2.00 | ≤1.00 | ≤0.20 | ≤0.15 | 8.00-10.00 | 可加入≤0.60 | 17.00-19.00 |

| NBC | 1215快削钢 | ≤0.09 | 0.75-1.05 | 0.04-0.09 | 0.26-0.35 | ||||

苏公网安备32058102001839

苏公网安备32058102001839